Simple Method in Refining, Definitive Result Formula!

The New Global Standard for Waste Engine Oil Treatment Low-temperature treatment technology reduces energy consumption by up to 70%.

A new era is beginning in the global recycling of waste motor oil.

A new era is beginning in the global recycling of waste motor oil. Our low-temperature treatment technology platform, developed with an advanced engineering approach, offers a modern solution that contributes to global sustainability goals.

Developed by Turkish scientist Kadir Dogan, the system eliminates the high temperatures of 500°C required in traditional methods, enabling recovery at only 50-95°C. This innovation reduces energy consumption and minimizes environmental impact. Bartu Engine Oils is handling the patent application and coordinating the process.

100% Refined/Additive-Free Engine Oil

We offer a sustainable and highly efficient purification experience with our innovative technology that eliminates the high temperature requirement of 500 °C in traditional systems.

1. THE REASONS BEHIND THE IMPOSITION OF HIGH TEMPERATURE SYSTEMS

The pressure placed on companies to adopt high-temperature systems is driven not only by technical considerations, but also by economic ones.

Volumetric Necessity

Large-scale facilities processing thousands of tons of waste oil per day worldwide have standardized high energy-intensity methods (distillation / cracking) in order to accelerate the process and maintain continuous flow.

Energy Cost

The energy required to reach temperatures of 300 °C and above can completely eliminate profit margins for small and medium-sized facilities.

Equipment Lifetime

Tar formation, carbon shell buildup at the reactor bottom, and corrosion in high-temperature systems significantly increase maintenance costs.

Quality Control

Maintaining vacuum stability on a small scale is difficult. When vacuum levels drop, high temperatures damage the oil's molecular structure.

In contrast, within the 95–110 °C range, preserving the molecular chains of the oil is far easier.

Regulatory Habit

Existing environmental regulations are generally based on vacuum distillation + hydro-treatment technologies used by large refineries.

Since these methods are accepted as Best Available Techniques (BAT), they are often presented as the only viable option for small and medium-sized enterprises as well.

By-Product Demand

Because high temperatures produce not only base oil but also diesel- and gasoline-like light fractions, these systems receive greater investment support during periods of energy crisis.

2. OPERATIONAL REALITY

The crisis faced by high-temperature producers stems from engineering assumptions that do not align with real-world field conditions.

Energy and Maintenance Costs

Rising energy prices in 2026 have rendered systems operating above 300 °C economically unsustainable.

Tar Formation and Degradation

At high temperatures, oil molecules break down (cracking).

This leads to severe fouling in reactors, tar formation, and product loss.

Patents That Fail in the Field

Experiments conducted in laboratory environments with pure chemicals fail when applied to real waste oil containing sulfur, water, heavy metals, and soot.

The patent we developed through three years of field testing has therefore become a lifeline for those seeking a system that actually works in practice.

3. WHY DOES THE ENERGY SECTOR INSIST ON HIGH TEMPERATURES?

This is a legitimate question. The insistence on high temperatures is driven not only by technical factors, but also by economic and strategic considerations.

Equipment and Technology Sales

High-temperature vacuum distillation plants are massive and extremely expensive systems.

For global companies selling such technologies, our low-temperature, simple, and practical system represents a disruptive innovation that threatens a multi-billion-dollar technology market.

Centralized Control

Due to their complexity, high-temperature plants can only be established by large capital groups.

Our method democratizes refining, enabling small and medium-sized enterprises to produce high-quality output as well.

This poses a serious challenge to the market dominance of major energy players.

Energy Consumption Cycle

Higher temperatures mean higher consumption of natural gas or electricity.

For energy suppliers, an inefficient (energy-intensive) system generates more revenue than an efficient one.

4. OUR POSITION: WHEN FIELD EXPERIENCE DEFEATS THEORY

The main reason our patent has attracted such strong interest is that paper-based engineering fails to account for the variable nature of waste oil.

Waste oil is not a homogeneous substance; it contains all kinds of contaminants.

High temperatures may work in sterile laboratory conditions, but in the field, with contaminated oil, those temperatures literally "cook" the oil — resulting in the tar formation you have personally experienced.

At this point, engineering must not rely on memorized formulas, but function as a reasoning mechanism capable of analyzing cause-and-effect relationships.

When we demonstrate the contradiction between theoretical imposition and practical field success using technical parameters, existing industrial data clearly confirms this reality.

5. TECHNICAL FOUNDATIONS SUPPORTING OUR APPROACH

Molecular Stability

Low temperatures preserve the natural structure of base oil, including its viscosity index.

By focusing solely on separating contaminants rather than breaking molecular chains, the resulting product is significantly more stable.

Carbon Footprint

As of 2026, under increasing decarbonization pressure, our method provides a strategic advantage for refineries due to its substantially lower energy consumption.

CONCLUSION

Our success is a concrete demonstration of the principle that engineering is not just about calculations, but about understanding the language of the material in the field.

Global interest in our system shows that paper-based theories have failed in real-world conditions, and that the industry is now open to a simple, sustainable, and proven solution — namely, our patent.

The year 2026 is being recorded as the point at which low-energy, high-efficiency technologies are no longer alternatives, but are becoming the new industry standard.

Our Working Approach

At Bartu Engine Oils, we do not market our patented waste engine oil recycling technology through videos or digitally manipulated content.

In this industry, video-based presentations can often create misleading perceptions and fail to reflect real process conditions.

For this reason, we present and license our technology through:

-

On-site demonstrations

-

Real waste oil

-

Actual operating conditions

-

Hands-on application

Our licensing process is based on mutual trust, clear technical explanation, and formal agreements.

Critical technical details are shared only with serious and authorized parties.

Bartu Engine Oils focuses on long-term, sustainable partnerships, not short-term sales.

Stand by Recycling...

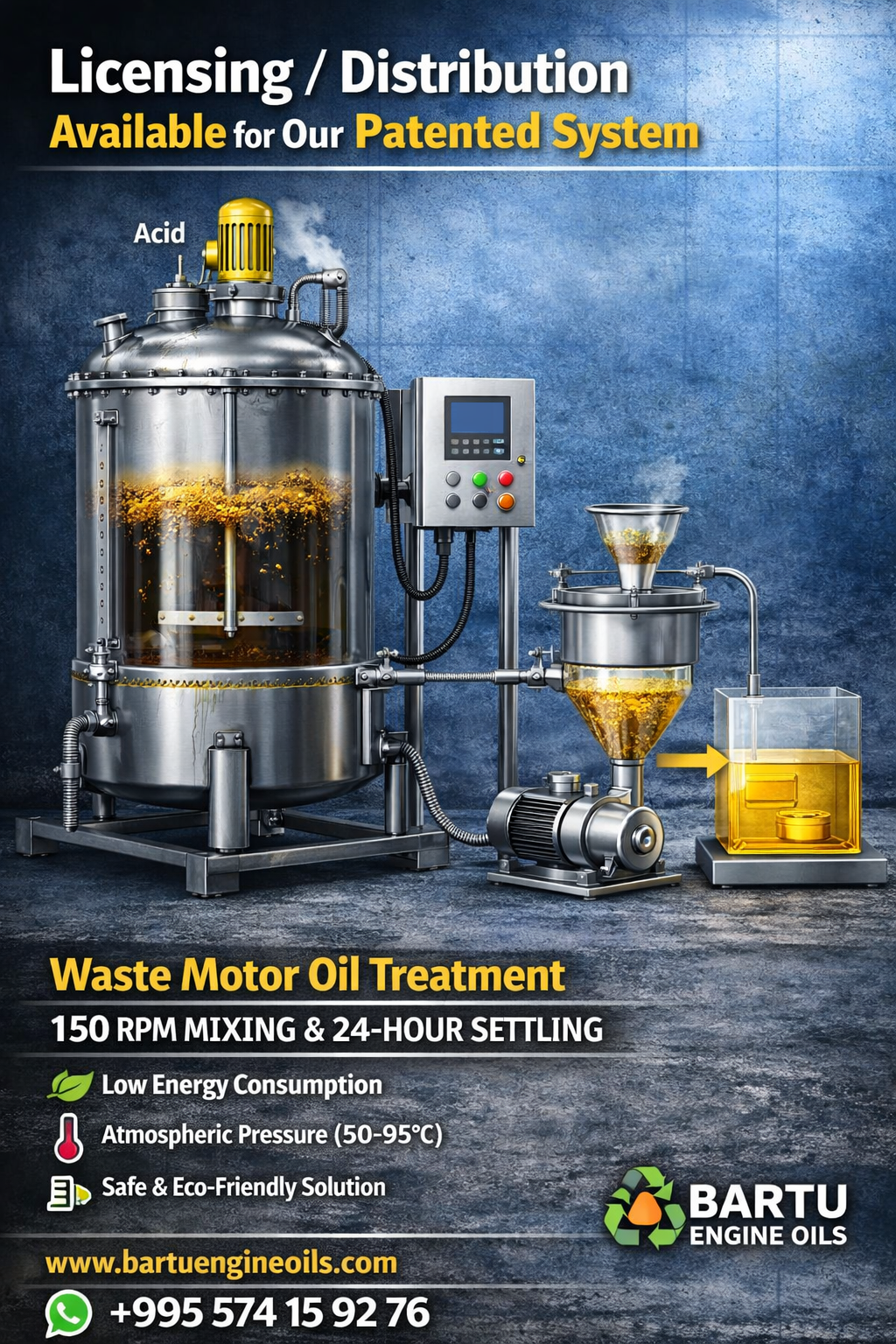

Our system is designed for continuous operation using

500-liter,

1,000-liter,

5,000-liter,

10,000-liter, and

20,000-liter mixing tanks.

Each processed batch is transferred to a separate settling tank and left to rest. In this way, an average mixing time of approximately 3 hours is ensured for each batch, while the system continues to operate continuously and without interruption.

This formula invention enables the purification and refinement of waste engine oil from harmful components thanks to certain component ratios, process sequence and parameters.

Bartu Engine Oils is an innovative company specializing in engine oil recycling. We contribute to a sustainable future with our environmentally friendly solutions.

An important reminder...

Waste motor oil cannot be refined with a mixer tank alone.

The mixer tank must be used together with our patented formula as a complete system.

"Environmentally Friendly Engine Oils"

Definitive conversion of waste engine oil with formula...

- Our invention concerns a chemical kit specifically designed for the refining of waste motor oil and the refining method it uses. The specified ingredients, ratios, process sequence, and process parameters help purify the oil of harmful components and improve its color and odor.

The powerful formula for waste engine oil recycling!

As Bartu Engine Oils, with the formula we invented ourselves;

- From waste engine oils without any technical skills,

- By applying a specific process sequence, in an open tank,

- You can obtain clean oil without pressure at a speed of 150-200 rpm and temperatures between 50-95*C.

Order our services

Please leave us your details and we'll get back to you as soon as possible.

Communication

As Bartu Engine Oils, we are proud to provide quality engine oils to the engine oil industry.

BARTU CONSTRUCTION AND RECYCLING IND. AND TRADE CO. LTD.

Registration Number: 431437572

Origin: Georgia

Davitaşvili no: 6 Telavi/Gürcistan